- SIMPLIFY 3D PRINTING HOW TO

- SIMPLIFY 3D PRINTING CRACK SERIAL

- SIMPLIFY 3D PRINTING INSTALL

- SIMPLIFY 3D PRINTING SOFTWARE UPGRADE

- SIMPLIFY 3D PRINTING FULL

DA: 15 PA: 39 MOZ Rank: 54 Download Abylon LOGON V16.00.2 + Activation Crack

SIMPLIFY 3D PRINTING FULL

Sign up for notifications near expirationĪbuse Phone: +1.4805240066 Full details Top 10 Hosting Providers Registrar URL You can check the 9 Websites and blacklist ip address on this server Domain information This domain has been created 3 years, 205 days ago, remaining 159 days. has server used 172.67.200.101 (United States) ping response time Hosted in Cloudflare, Inc.

SIMPLIFY 3D PRINTING INSTALL

I guarantee you can install Simplif圓D 4.1.0 successfully if you follow that instruction.

SIMPLIFY 3D PRINTING HOW TO

Inside folder Simplif圓D 4.1.0, already have crack’s file and instruction how to install Simplif圓D 4.1.0 step by step.

SIMPLIFY 3D PRINTING SOFTWARE UPGRADE

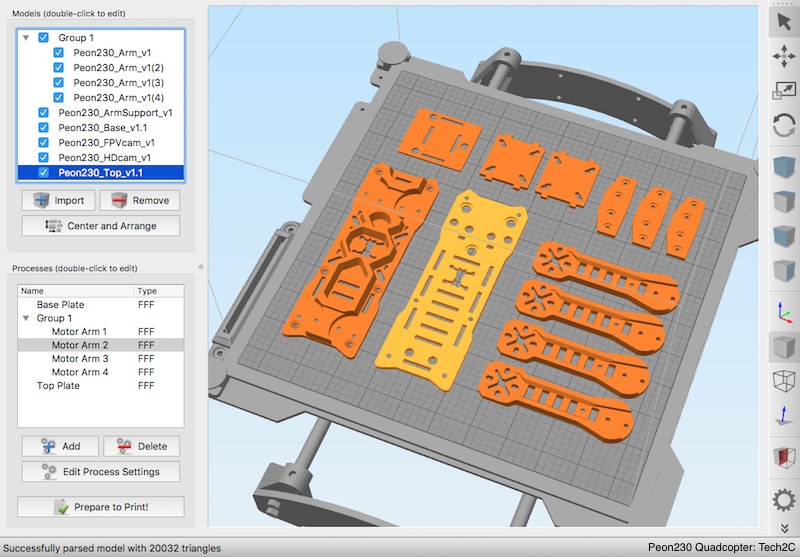

Better instructions meanbetter prints, so a simple software upgrade makes all thedifference in the world.In fact, more than 90% of experts agree that 3D printing softwarehas the greatest impact on print quality, even more so than the 3Dprinter.

SIMPLIFY 3D PRINTING CRACK SERIAL

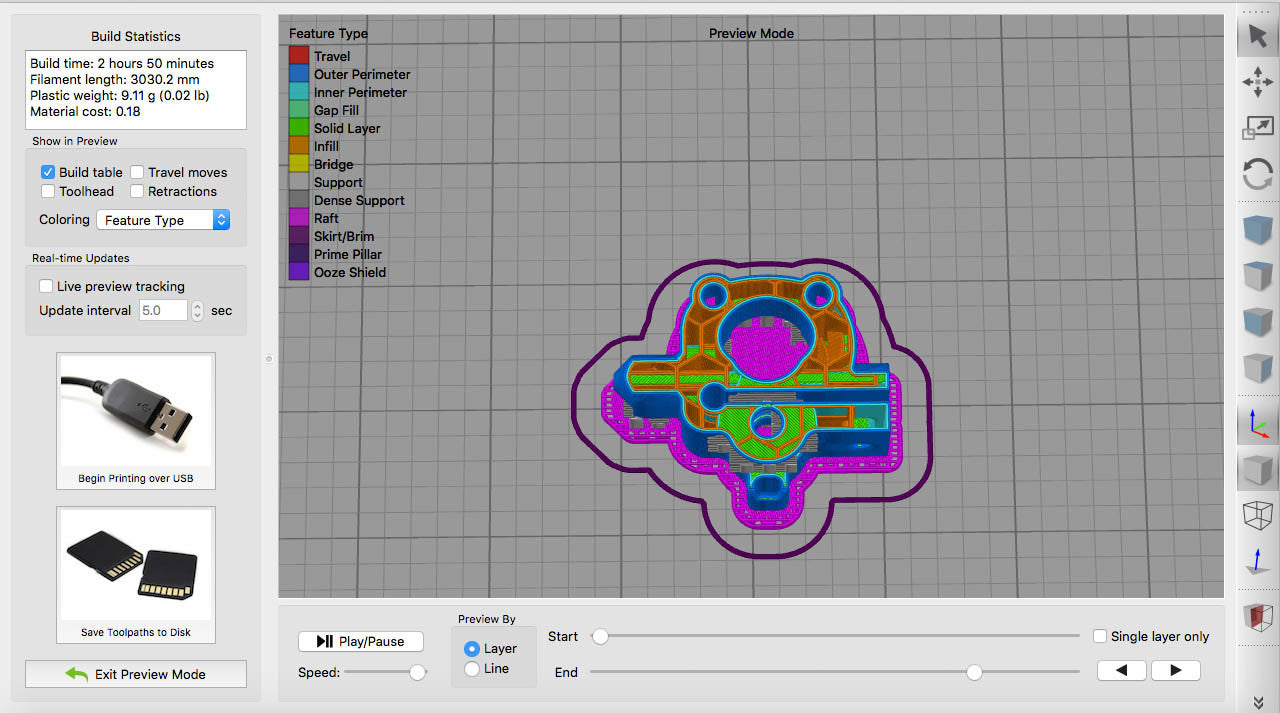

ScreenShots: Software Description: Simplif圓D v4.0.1 x86/圆4 Crack Serial Simplif圓D translates 3D models intoinstructions your printer understands.

a) That height needs to be adjusted frequently.G1 Z50 if the part have to restart anywhere beetween 0mm height and 50mm height, it does have two problems, one being a very big one: 2) While it is true that you could add a last line in the starting custom gcode script stating f.e.1) Printing starting at highers levels than 0mm still have a sequence that first moves the head IN the already partially printed part, en then up but that's too late, the harm is done and the part is no longer where it should be.It is version 3.02 now, and I still see that

Hello S3D team, I'd like to digg this one up. P.S Simplif圓D, if you're reading, please make this Feature useable otherwise, why go into the hassle of including it!! So I inserted the line G1 Z-50 F3000 as the very last line in the start up script but that didn't work. The bed then moves to the set height (Again it makes absolutely no sense why it's done this way!)īut since I've moved it away initially, there's the gap (I believe 50) from where the bed should be. So after purging, the extruders move to location over the print bed where it'll be starting the Print. (As an aside, this wouldn't have been a problem if S3D didn't change the purge location. This prevents the extruders hitting the part on the way to the purge location So I inserted the code G1 Z50 F3000 to first move the bed away before the extruders move to the purge location. I tried to insert the line but it seems I have to compensate for it in the actual gcode and not the start script. But not large enough that you exceed your Z-axis stroke Just make the Z-value something large so that the extruder will be moving DOWN to your print instead of up through it. You can just add one line at the end of your starting gcode script if you want to avoid this in the future.

0 kommentar(er)

0 kommentar(er)